Our Work Methodology

Production at the Company’s Factory

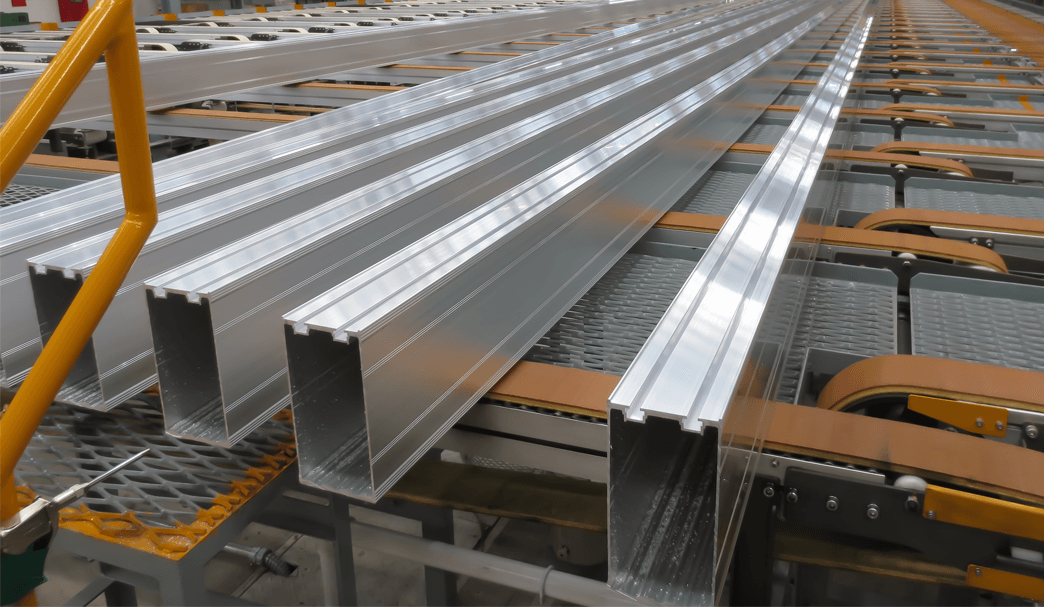

The Company’s factories are located in the Emek Hefer Industrial Park, where veteran employees emphasize quality control and use advanced technologies and practices.

The 8,000 m² (9,568 sq. yd.) manufacturing area and metal shop employ CNC machines for cutting and processing profiles; other CNC machines are used for cutting and grooving the world’s advanced panel metals enabling the greatest exactness, without human contact; all managed by skilled personnel.

Debi Aluminum’s manufacturing department is able to simultaneously respond to a large number of projects, while keeping stringent schedules and product quality.

We have a unique curtain-wall facade inspection facility for developing the product, where all its components are thoroughly tested for architectural and static aspects and for withstanding extreme weather conditions. The facility can inspect walls of up to 6 m wide and 8 m high, allowing for inspection of two consecutive floors before assembling at the building site.

Planning and Adapting Solutions for the Customer

Debi Aluminum’s state-of-the-art design department is a leader in the aluminum sector.

This department is staffed with engineers and technicians, planning and accompanying the entire project throughout, including meticulous preparations, using 2D and 3D software, and finding creative solutions for complex projects, adhering to the project’s architect plans.

All of the Company’s plans are being examined by a Structural Engineer who calculates the durability of the project’s various systems (aluminum and steel) on the various loads prevailing at the project site. The team adheres to the stringent standards and safety procedures until the architects, consultants, and the project’s client finally approve the planning.

The planning department follows each project by creating an initial mock-up model until all the factors are approved. Further along, the planner accompanies the project implementation onsite until completion to the customer’s satisfaction.

Purchasing Division

The Company works with leading suppliers in Israel and abroad. The connections made working together over the decades, enable the Company to obtain target prices which provide a fair and competitive response to its clients.

The Company’s purchasing and logistics department assists the organization in coping with complex logistical needs and tight delivery deadlines.

Onsite Installation

Project success is an outcome of proper and exact planning by the onsite installation department, which is staffed by installation teams with many years of experience. Additionally, the dedicates site manager closely supervises the project, ensuring the best possible installation.

Providing Service and Hired Staff

Debi Aluminum’s has its service teams available to customers during the testing and warranty period and after as well. The professional teams are experts in aluminum work, providing professional and efficient service for the Company’s clients on projects spread across the entire country.

The team responds to each of our customer’s demands, from handling a broken window hinge to replacing the in-glass shade in a high-rise building.

Debi Scaffolding and Protection Nets

Debi Enterprises, Ltd. is a Debi Aluminum owned subsidiary specializing in scaffolding for outdoor work and protection nets. The Company has an extensive scaffolding fleet, managed by teams who are experts at installing and constructing hanging systems adapted to various site requirements for each project.

Engineers, the Standards Institute and the Company’s safety officer closely supervise these teams.

Debi “Tigers” Soccer Team

At Debi Aluminum, employee welfare is highly valued.

Debi Aluminum has a soccer team playing against other local workplace teams.

We at Debi Aluminum ensure that employees have a sense of belonging, identification, and commitment through enjoyable bonding activities and concern for their safety.